There are car manufacturers who changed the design of their vehicles, often radically, many times in their history, such as Opel, Mercedes-Benz and basically every American company. Other car manufacturers kept to the same design for decades, making only small changes to small details, such as the Volkswagen Beetle, Citroen 2CV, British Leyland Mini and Renault 4. These cars are famous and legendary today, recognized all over the world because they retained their distinctive character. The F9, while neither famous nor legendary, belongs to this second group as it retained the same body shape from the time it was first revealed in 1939 until production stopped in 1964.

One thing I always found a little disappointing about these 'eternal' car designs was that the changes and updates that were made over time made them look more and more ugly. The windows became bigger for better vision, the body was widened for passenger comfort, more chromed trims were added to follow some fashion trends. While these changes fulfilled customers' rising expectations, the formerly pure and balanced original design of the car’s body was compromised.

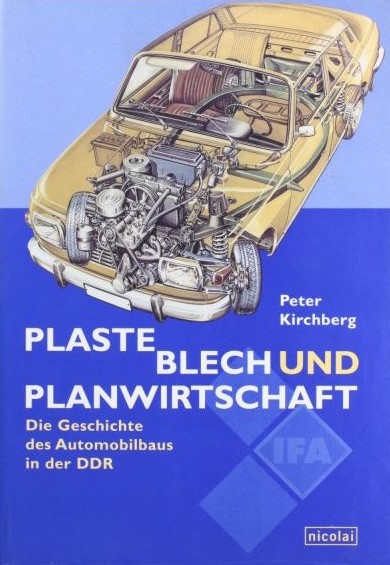

So, for my F9 replica, I decided to 'go back to the roots.' In Zwickau they were very quick to completely revise the front, fenders and bonnet of the new car. The IFA-bible contains pictures of two pre-serial F9s, both from 1948, but with big differences in technical details and styling.

The car shown on pages 73 and 74 (above) retains the fenders and narrow bonnet of the pre-war prototype, with the gasoline tank in the back, small door handles and aluminum trim on the split window (my project).

The other version from the same year is shown on page 71 and has new IFA-fenders, the bonnet is 6cm wider, new bumpers, the gasoline tank mounted in the front, and bigger door handles. The reason for the existence of two different pre-serial cars lies - once again - in the separation of Germany and the 'cold war'. The body parts for the original prewar prototypes were produced by the Baur Karosseriewerkes in Stuttgart in what would become West-Germany and shipped to Auto-Union for assembly. Post-war, Zwickau was able to build their first F9 from spare and salvaged parts, but these were no longer available for the planned serial production. New body parts had to be manufactured from scratch, along with all the necessary pressing tools. This gave Zwickau engineers the opportunity to give the car a new face and address the numerous tight clearances within the engine compartment. The 'closed' position of the bonnet was set higher by 30mm. The front of the bonnet was made wider by 60mm, and the side walls of the engine compartment were set further apart.

Editor's Note – An Auto-Union memorandum exists from the pre-war development period noting that the narrow engine and gearbox clearances made repairs ‘in chassis’ extremely difficult. The use of a specially constructed spring engine hoist was essential for installing and removing the engine, thanks to which it took three men "only" four hours to remove the entire drive unit.

As there was no gasoline pump available in East Germany at that time, the gasoline tank was moved from the trunk into the engine compartment, using gravity feed like the prewar F8.

It is important at this point to review what was happening over in Ingolstadt in West Germany, where the new Auto-Union was attempting to revive their version of the DKW F9. As we know, Auto-Union lost their copy of the F9 when the British seized William Werner’s car in 1945. By a stroke of good fortune, Auto-Union recovered a set of complete, but damaged body presses from the tooling company, Allgaier, which enabled them to begin stamping out F9 body panels to fit over the prewar F8 chassis. This became the F89P New Meisterklasse, which went on sale in 1950. As this car was powered by the transverse mounted twin cylinder 700cc engine, Auto-Union too were forced to redesign the front end of the vehicle.

The pictures above show several attempts to update of the design on the prototype in Ingolstadt to differentiate it from the IFA F9, which went on sale a year earlier. These attempts eventually led to the serial version of F89P with the shorter bonnet and a new horizontal false radiator screen mounted across the car’s face. To provide more space for the long lower horizontal trims of this new radiator grill and the new big front bumper, it was necessary to set the front headlamps about 3cm higher than in the prewar DKW F9 prototypes. They set the lamps in higher position not by creating a new fender but by TURNING THE FENDER UPWARDS! The turning point was the lower corner of the fender, where it flowed into the door.

Understanding this process, I presumed the fenders of the F89P and the F9-prototype were produced by the same pressing tools from BAUR in Stuttgart, but the front corners of the F89P-version were cut off to fit the bumper and radiator grill, and the rear corner where the wing meets the door cut off slightly to account for the upturned mounting position.

The DKW F89P donor body came from Dieter Weingold's stockpile.

The next step was to cut the IFA bonnet down its central axis from the front almost to the end and push the front ends over each other in order to reduce the front aspect by 6cm, then weld together.

Internally, the side walls of the engine compartment were adjusted to the new fenders' positions.

My assumptions were immediately confirmed when I test mounted the IFA-bonnet onto the body after mounting the F89P-fenders in the original (F9) lowered position (with front lamps now 3cm lower). The closing lines of bonnet and fender fitted together as though these parts have always belonged to the same car.

The recreation now begins to look correct.

An early IFA F9 split rear window replaced the F89P rear window

The Dashboard.

The famous VW Beetle's marketing managers obviously weren't particularly keen on attracting more customers by providing their product with the latest in styling, design and technology. The Beetle was the last German car that was still equipped with a symmetric dashboard with two glove boxes and instruments arranged symmetrically left and right around the central axis. The Beetle's asymmetric dashboard was only introduced in 1953. The Beetle was also the last car still using mechanical direction indicators (Winkers) instead of indicator lamps (Blinkers). These were not changed until 1958.

When the shape and design of F9 were created in 1939, it was very modern to accentuate the central axis of the car body with split windows and shining trims on bonnet and between the split front glass.

I did not consider using a dashboard from an F89P or IFA F9 from 1954 or later although these were readily available.

The red 'Werner car', as has been restored today, has something like that, which is kind of disappointing as it is not correct to the photographs we have of the F9 prototypes.

There were only two possibilities for my project – manufacture an F9-prototype dashboard as seen in historical pictures or obtain an F9 serial dashboard as shown in IFA DKW F9 parts list from 12\1951. I chose the serial one for three reasons:

1. I had the good fortune to borrow an original one from German DKW-enthusiast Henryk Kindt (the only one I’ve ever seen in my life as they are very rare). He gave me permission to restore it and let Beauvary GmbH in Aachen, Germany, reproduce it.

2. The rear-view photograph of the pre-serial IFA F9 from 1948 (my car) in the IFA-bible page 74 shows us that the car show it was already equipped with this new serial dashboard.

3. When I made the arrangement with Henryk Kindt in 2015, the Estonian F9 had not yet be discovered. Despite the significant modifications this car has been through, the car still has the original F9-prototype dashboard. It would have been a nice idea to reproduce this one, too.

Undoubtedly, Auto-Union planned a completely symmetric F9-dashboard, but for the IFA F9, the left-hand glove box is smaller size than that one on the right side. This was a consequence of the necessity to move the gasoline tank into the engine bay. This left no space for the wiper engine.

Beauvary GmbH in Aachen (www.beauvary.com) offers 'small-batch 3-D formed sheet metal manufacturing for boats, oldtimer parts, art and design objects.' This wasn't any kind of cheap solution and required a lot of manual after-work, but I finally got exactly what I wanted. Knowing the early F9 would attract more enthusiasts soon, I let Beauvary produce 5 pieces.

Test fitting the dashboard

After painting (by my ten year old son), the result is marvelous.

The Bumpers.

There are obvious differences with the bumpers on the Werner car, as restored, which were obviously tinkered with by some apprentices in the Audi museum workshop by looking at the historical pictures.

I found two prewar bumpers in Dieter Weigold's massive collection of parts that fitted the car perfectly. These are real historical car accessories from the manufacturer, Friese. Friese manufactured bumpers for the DKW F7 and F8 before the war, as well as the Mercedes-Benz 170 and Audi and Wanderer cars.

And fitted, they look perfect.

Unfortunately I was missing the bumper horns so I had to call on Beauvary’s service again.

The molds for the horn templates were carved in hard rubber.

Rear view of the car

By Winfried Kuhl

The IFA F9 Project Part One - https://dkwautounionproject.blogspot.com/2021/08/1948-ifa-f9-replica-project.html

The IFA F9 Project Part Two - The Engine - https://dkwautounionproject.blogspot.com/2021/09/1948-ifa-f9-replica-project-part-two.html

The IFA F9 Project Part Three - The Chassis - https://dkwautounionproject.blogspot.com/2021/09/1948-ifa-f9-replica-project-part-three.html

Development of the IFA F9 - https://dkwautounionproject.blogspot.com/2020/07/the-development-of-ifa-f9.html

1953 Overview of the development of the IFA F9 - https://dkwautounionproject.blogspot.com/2021/09/1953-deutsche-und-auslander.html

1954 IFA F9 Ersatzteilelist - https://dkwautounionproject.blogspot.com/2021/12/1954-ifa-f9-ersatzteilelist.html